Common USB cable terms

If you are new to ordering custom cables some of the terms you might not be familiar with. Here I list some of the most commonly used terms myself and other makers use.

Host cable: Portion that goes to a computer or charger

Device Cable: Portion that connects to the device being used IE: Phone, printer, J2534 interface or keyboard

Ferrite Cores: Used to filter EMI (Noise) from a cable

Detachable: A 2 piece connector that allows 2 halves of a cable to connect

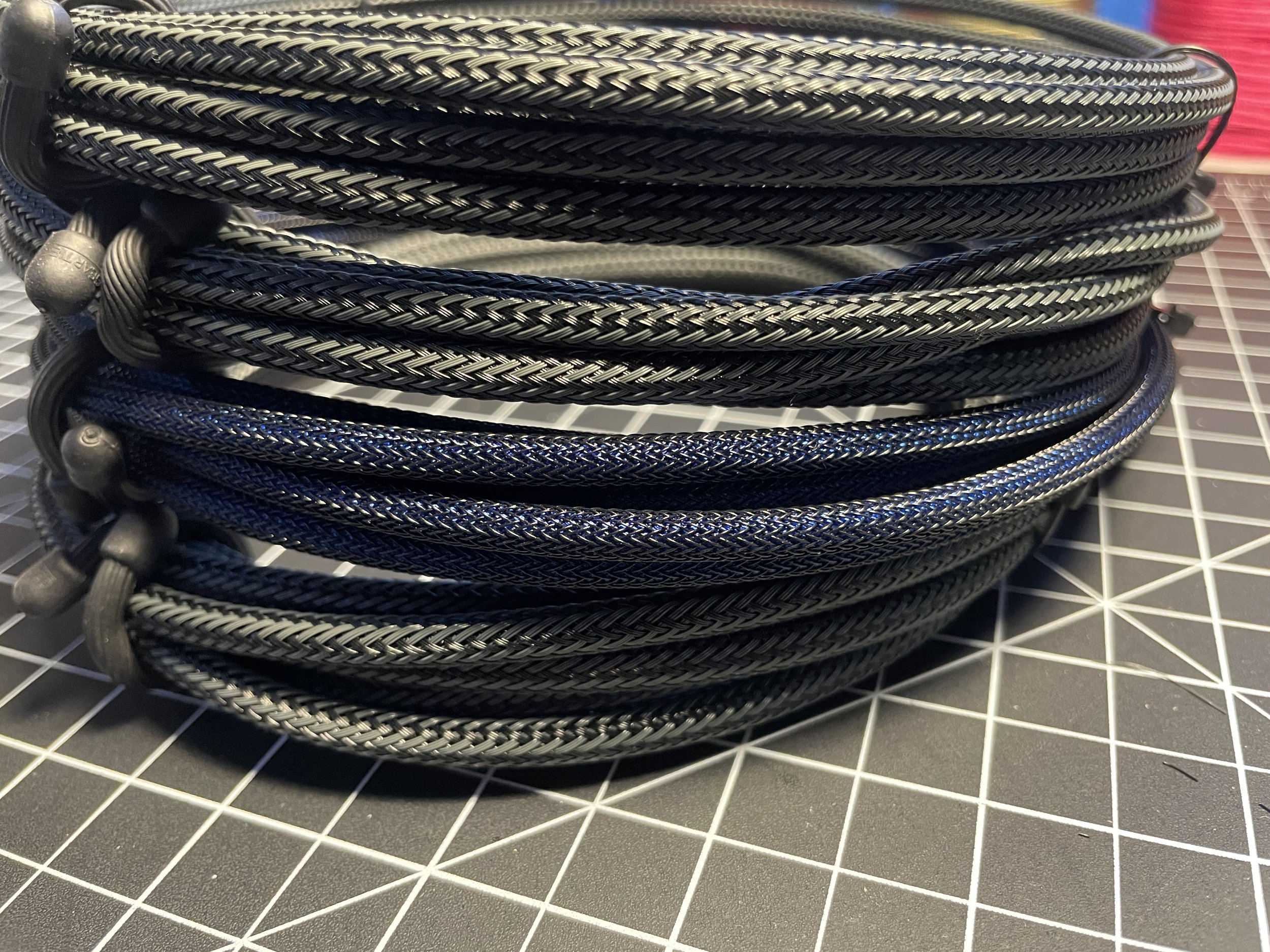

MDPC-X

MDPC-X: High quality sleeving made in Germany. MDPC-X has a tighter weave which means the inner sleeve is not very visible or not visible at all (unless using transparent sleeving). The upside is MDPC-X has extended color ranges

PET-X braided sleeving has self-extinguishing properties opposing to Nylon materials, which can burn suddenly and quickly.

MDPC-X PET-X fibres are water repellent, stain resistant and - when exposed to UV daylight - will keep their color quality and material structure intact, opposing to "cotton style" Nylon based materials.

MDPC-X cable sleeves are ready for extreme environments. Our materials withstand temperatures from -58°C to +155°C. Short term peaks of 215°C can also be handled without structural degradation.

The cable sleeves can be melted at 240°C or higher temperatures. Melting can be controlled very well and used on purpose to fix the sleeving ends to the wire insulation or a structure on the object which serves as a holder.

Excellent resistance to chemicals like oil, cleaning agents, gasoline and substances like sweat and salt water.

Sleeving

Only genuine Techflex and MDPC-X is used on my cables for the highest quailty and consistency

Techflex

Techflex: The FLEXO PET grade is used in electronics, automotive, marine and industrial wire harnessing applications where cost efficiency and durability are critical. PT is braided from 10 mil polyethylene terephthalate (PET) monofilament yarns

You are probally pretty familiar with this type of sleeving as it’s the most common. Great for a general purpose outer sleeving where you want the inner sleeve to show or in situations where sharp objects or high heat or abrasion is an issue. IMO…MPDC-X is a better choice for an outer sleeving for automotive and everyday use. Click the button bellow for information on Techflex PET